Main benefits

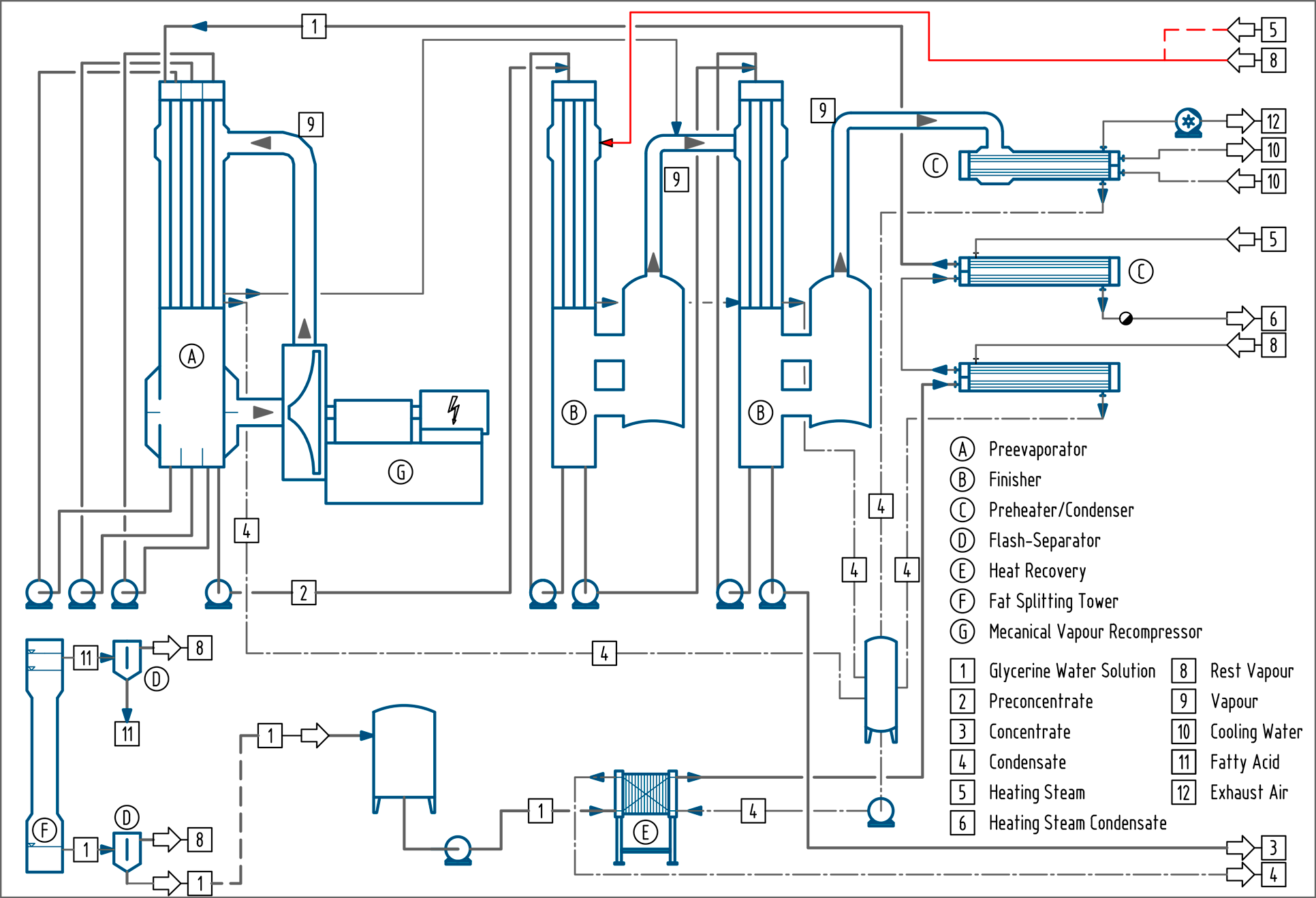

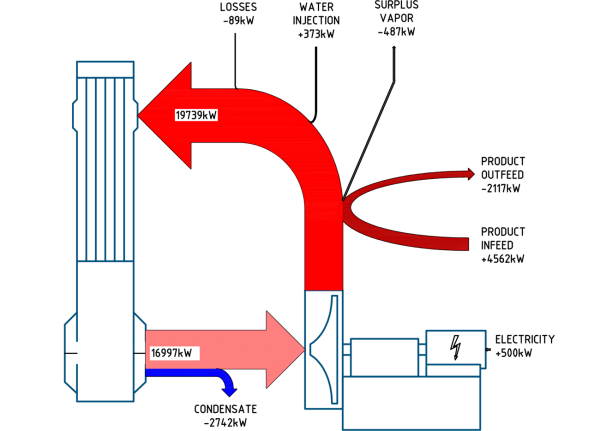

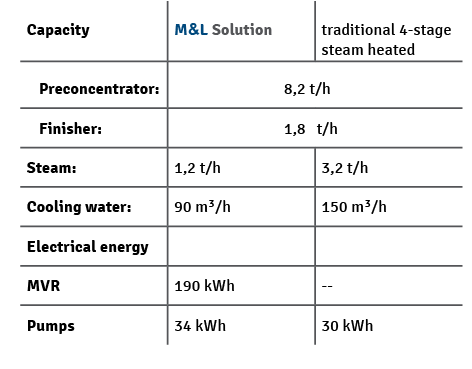

Mechanical vapour recompressor (MVR), combined with direct heating by exhaust flash steam or heating steam

minimal cooling water consumption

minimal heating steam consumption

minimal heating steam consumption

Falling film evaporator

short retention time

high wetting through

recirculation low fouling

minimal cleaning effort

minimal burning of glyceric

high wetting through

recirculation low fouling

minimal cleaning effort

minimal burning of glyceric

Subsequent concentration to pure glycerine (99,9%) with M&L – technology possible

highest purity

Glycerine Pre-Concentration

In the lower concentration range glycerine water from the fat splitting tower or ester interchange will be concentrated by falling film evaporator with MVR. With increasing of boiling point further concentration by direct steam heated evaporation. Example: 10 t/h evaporation capacity with an evaporation rate of 1 : 6,66 (concentration from von 12% to 80%)