Description

high efficency with reduced power consumption.

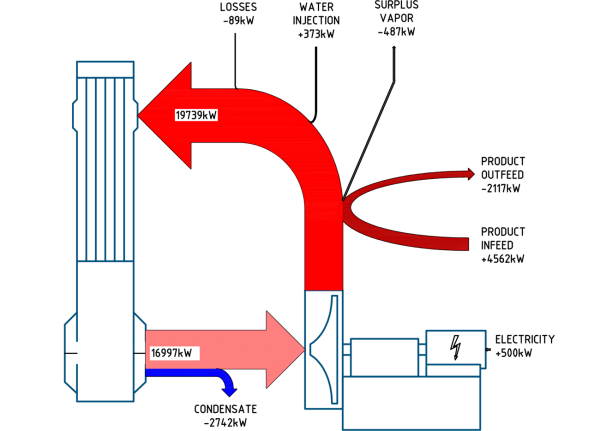

The vapour which arises from the evaporation of the product can be fed back into the process as heating medium with the help of a mechanical vapour recompressor.

With a MVR the vapours from evaporation get compressed in a radial ventilator. With this compression the temperature- and energy-level of the vapour will be increased up to 8° C . With a MVR the energy in the product vapour is not lost and will be reused as steam for heating the process of evaporation.

The electrical energy used by the MVR motor is small compared to the energy content of the vapour. The result is an enormous saving of energy.

Main benefits

Energy of product vapour that normally is lost can be used for heating

that normally is lost can be used for heating

Less energy cost due to saving of live steam

due to saving of live steam

Only the electrical energy for increasing the temperature level is needed

for increasing the temperature level is needed

Reduced CO2 emission

for a better environment

Fast ROI

between 5 to 10 years