Descpription

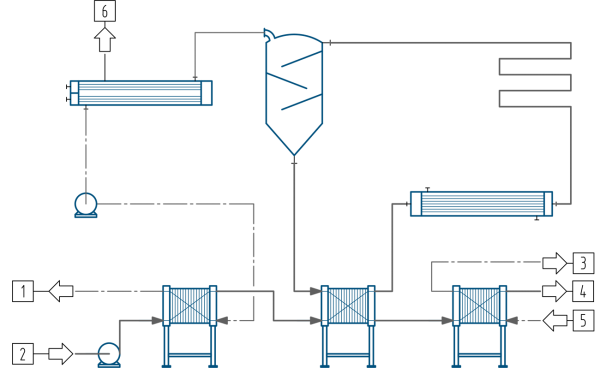

Flash coolers utilize the latent heat of the product for evaporation. In hygienical designed vaccum vessels the product is distributed on a big surface, allowing for gentle and foam free evaporation of water. Beside the cocentration of your product, a positive side effect is the gentle cooling of the product towards the evaporation temperature. Short residence time, low heat and low shear force impact are the characteristics of this process, combined with hygenic designed appartusses and components.

M&L Engineering delivers to you a specificly tailored process, with optimum energy and performance effienecy.

Main benefits

Effective cooling

also for viscous products

Heat recuperation possible

by vapor re-usage

Hygienic design

allows efficient production with short cleaning downtime

Easy and low cost maintenance

compared to complicated heat exchangers

Concentration, cooling and pasteurization

of product can be combined in ONE process