Descpription

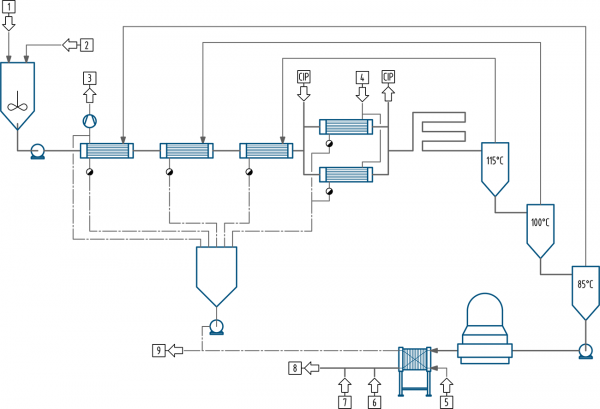

Continuous wort production with high gravity up to 21 °P can be handled optimally with a high temperature process. Incoming wort with a concentration of 16 °P is equalized and mixed with isomerized kettle hop extract in a feed tank.

Then the wort is subsequently heated up in tubular heat exchangers by regenerative condensation of vapours. In a final heat exchanger the wort is heated up to 130 °C by live steam. The final heat exchanger is executed redundantly for continuous operation also in case of heat exchanger fouling and need for cleaning.

At final temperature the wort is kept for a defined time of 150-180 seconds by regulating the flow through the system. After the heat holding section, the wort is flashed in three steps down to 85 °C. The vapours are used to heat up the incoming wort stream.

After the final flash step the wort is clarified by a centrifuge and the hot trub removed. Alternatively also a double whirlpool installation would be feasible. After cooling by a plate heat exchanger, the wort is aerated, pitched with yeast and transferred into the fermentation tank.

Main benefits

Heat energy consumption

Evaporation capacity

High Gravity

Cogeneration

Optimized DMS

Optimized color and Maillard-product handling